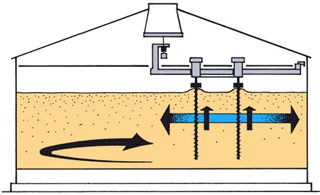

Whether you use hot or natural air, when you install a NECO stirring machine in your bin, drying will always be faster and more efficient. With the stirring machine, moisture content is more uniform throughout the bin thereby better preserving the quality of stored grain.

In operation, the hottest and driest grain at the bottom is moved upward. All grain in the bin is mixed and blended until moisture content is uniform. Unlike top-dry sytems, the risk of overdrying in some parts of the bin and underdrying in others is eliminated.

In operation, the hottest and driest grain at the bottom is moved upward. All grain in the bin is mixed and blended until moisture content is uniform. Unlike top-dry sytems, the risk of overdrying in some parts of the bin and underdrying in others is eliminated.

The gently rotating augers rotation lift the grain as they move around the bin. The patterns these augers follow cross and recross many times until every part of the bin has been thoroughly stirred.

Unique Stir-Rite features:

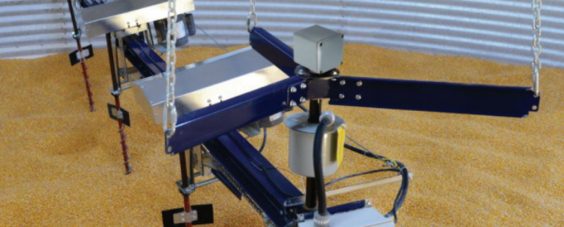

• Gooseneck pivot design suspends the inner end of the main beam in a way that permits the auger to move all the way to the bin center. The auger also comes within 7″ of the bin wall. The beam connecting point is movable to precisely match the Stir-Rite to your bin. This feature assures that Advanced Grain will have a Stir-Rite for you even is your bin is not standard size.

• The backbone of the Stir-Rite is a wide flange beam specifically chosen for its high ratio of strength and rigidity to weight. It’s very same kind used for bridges and other large structures!

• A rotating contact was specifically designed for this application. It has a heating element to reduce moisture condensation while drying.

• Because of the unique increasing pitch design, the augers start and advance through grain much more easily than uniform pitch augers. Distance between flights is smallest at the bottom then increases slightly toward the top. This allows for additional grain to enter the auger over its total length. This action helps loosen the all the grain in the bin. The looser grain eases the augers to travel and allows more air pass through thereby shortening drying times.

• Paddles on stirring augers are fabricated from flexible material. This is for safety and reduces the chance of damage to grain.

• Augers are hard-surfaced on the lifting faces to assure long life.

• The stirring auger is driven by a 1.5 HP motor specifically designed for this application. A V-belt drives the auger and is kept in proper tension by a self-adjusting motor mount. Outside augers turn faster than the inside auger. Speed of the auger is matched to the amount of grain it stirs.

• Heavy-duty gear-motor and forged bevel gears supply power to the hardened steel track drive wheel. In the event that an auger encounters an obstruction in the bin, a shear pin is built into this drive to protect mechanical components.

• Track support brackets use existing bin bolt holes in most cases. The track, manufactured from hot-rolled steel, is designed never to sag even in the wettest grain.

• Unique design of Stir-Rite allows for additional stirring auger(s) to be added later. This feature means that the Stir-Rite can grow with your operation.

• Driven by a double pitch chain, the positive drive moves all trollies back and forth in unison. A pivot arm is attached to the outer trolley, its other end is attached to a special link on the chain. The chain rotates around two sprockets. The pivot simply follows the chain reversing direction when it goes around each sprocket. This simple drive eliminates the need for any reversing switches. Positive chain drive prevents the possibility of slippage and is easy to adjust.

• Trolleys roll on long-life cast-iron rollers. Rollers are machined in such a way that they fit between the flanges of the beam. This eliminates the possibility of the trolley coming off during operation.

• All electrical connections and enclosures are moisture tight to deal with extreme conditions encountered in drying bins.